-

-

Customized service center for parts processing , Equipment of precision mechanical parts in use , The following problems are inevitable : 1、 Waste water 、 Waste liquid : Such as oil 、 Filth 、 Heavy metals Waste liquid , In addition, there are cooling and drainage with high temperature, etc ; 2、 Noise ...

-

-

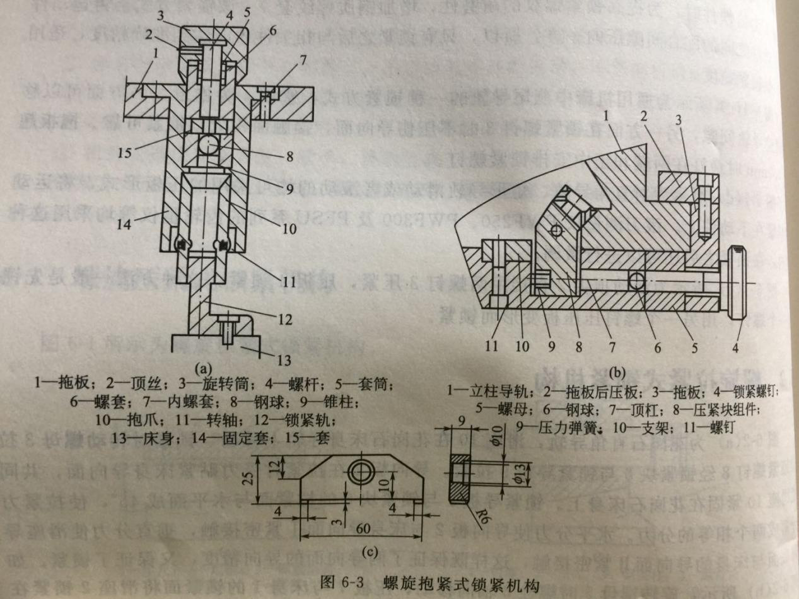

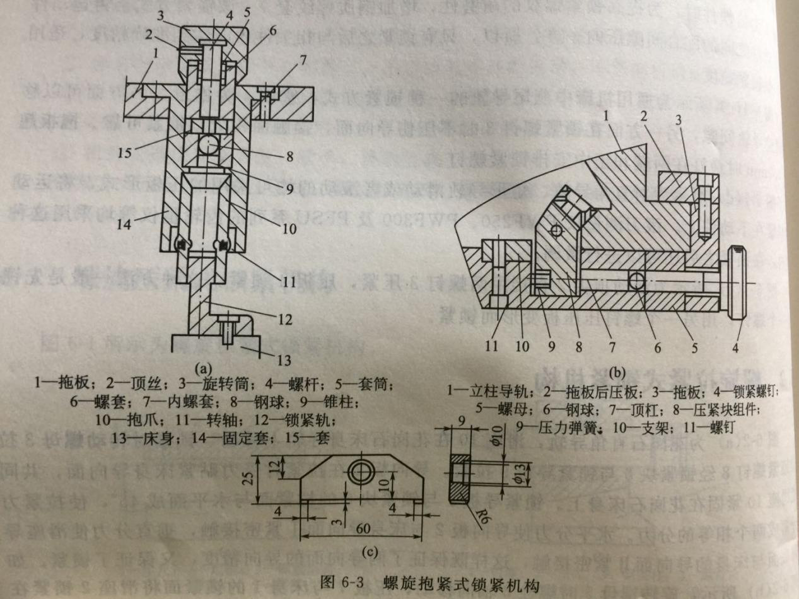

Chart 6-3 Screw type locking mechanism shown 。 As Chart 6-3(a), In the process of high precision parts customization , When turning the rotating cylinder clockwise 3 Time screw 4 Rotate and move down axially , Pass the ball 8 Push sleeve 7 Upper cone 9, Open both sides of the long end of the two levers ...

-

-

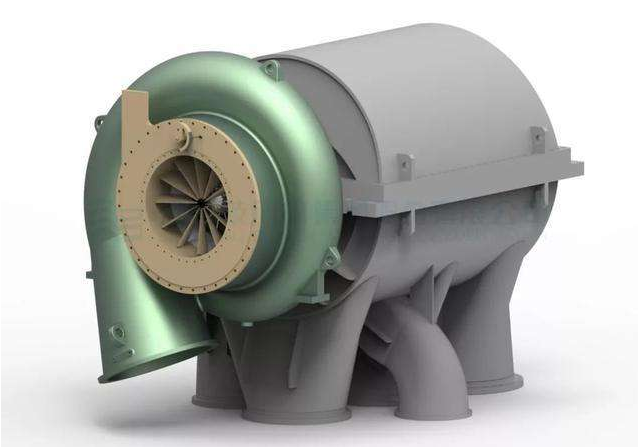

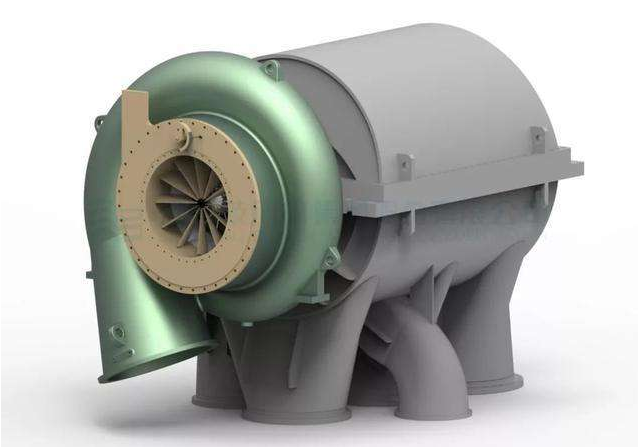

Stay Precision machining In process , Compressor body ( As Chart ) The compressed air is sent out by compressing the air inhaled with a screw , If the air compressor body is not maintained, the bearing will be damaged due to consumption ( Body bite ), It can't be repaired in case of severe damage , Even repair ...

-

-

In precision parts factory , Oil gas separator ( As Chart ) It is a part that separates screw lubricating oil and compressed air , In normal parts processing / Accessories processing in operation , Oil gas separator Of Service life Stay 3000 Hour or so , But the quality of lubricating oil and the air ...

-

-

Familiar with machining of mechanical parts , The shape of guide rail is right angle , Add anti dumping and force sealing structure or rectangular guide rail 。 In the parts factory , Their worktable ( Base ) And guide rails in all directions are made of natural granite materials 。 According to parts and components ...

cache

Processed in 0.031472 Second.